Best Low Pressure Die Casting Manufacturers in Pune

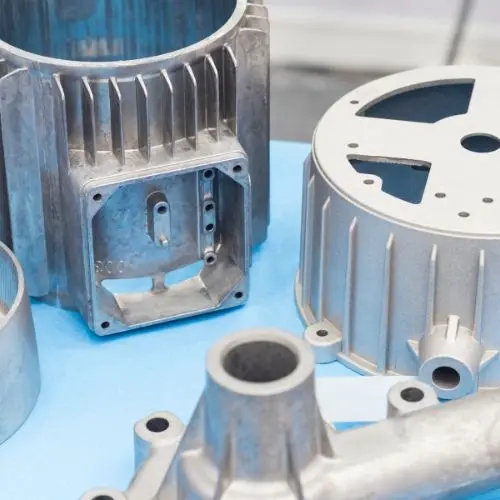

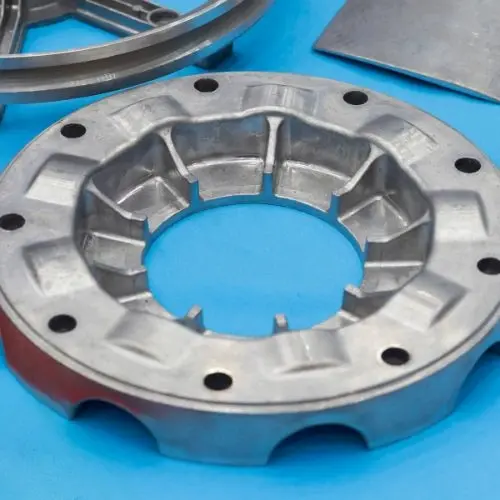

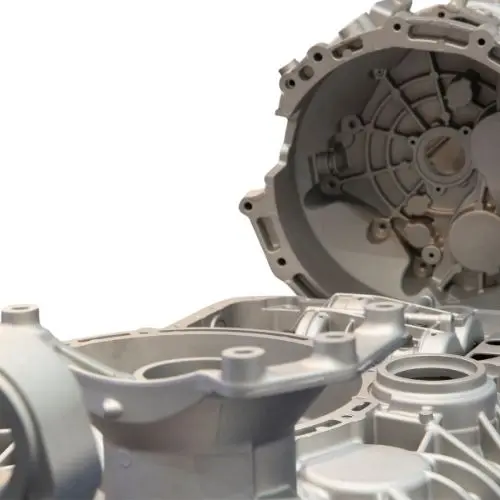

Low Pressure Die Casting (LPDC) is one of the most advanced casting methods used by Plasma Aluminium Diecasting to produce high-strength, lightweight, and dimensionally accurate aluminium components. The LPDC process ensures excellent surface finish, high repeatability, and minimal material wastage — making it ideal for industries that demand precision and reliability such as automotive, aerospace, and electrical applications.

What is Low Pressure Die Casting?

Low Pressure Die Casting is a process in which molten aluminium is forced into a die cavity under controlled low pressure (typically between 0.7 to 1.5 bar). Unlike gravity casting, LPDC fills the mold smoothly from the bottom upward, reducing turbulence and preventing air entrapment. This results in dense, porosity-free castings with superior mechanical strength.