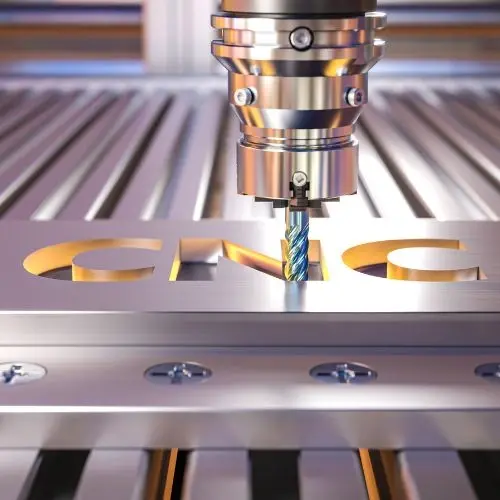

Best CNC Machining & Finishing Manufacturers in Pune

Precision Engineering. Superior Quality. Ready-to-Use Components.

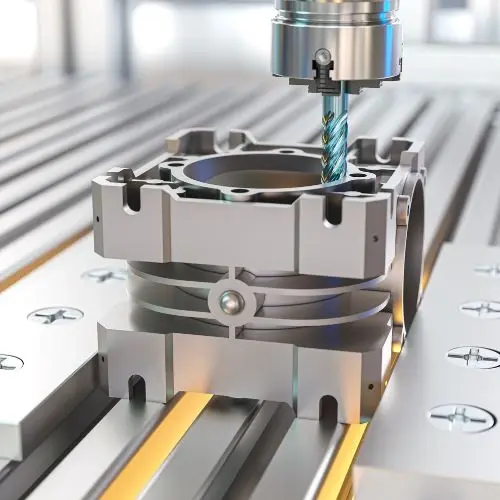

At our facility, we offer advanced CNC Machining and Finishing services to transform raw castings into precision-engineered, assembly-ready components. With state-of-the-art CNC machines and skilled operators, we ensure every part meets the tightest dimensional tolerances, perfect surface finishes, and exact design specifications required by global industries.